FEATURES |

1. |

The power-current capacity is large

since the thickness of conductor is 300〜400μm.

|

2. |

The conductor is covered with molded resin to shut out dust, therefore its

high reliability and safeness are ensured. |

3. |

The substrate is made of resin, which enables us to manufacture

various shapes of items with less labor and low cost.

|

4. |

Our resin material is heat-resistant, so we can work using a flow-soldering method. |

|

APPLICABLE PRODUCTS |

1. |

For power supply circuit parts in air-conditioners and the

exterior units.

|

2. |

For power supply circuit parts in washing machines, rice

cookers, and refrigerators, etc. |

3. |

The usage of a conductor as a part of ABS and power steering in

automobiles are highly recommendable. |

4. |

Applying a conductor in machine tools and robots enhances the dependability

of operation. |

If you are thinking to improve your products,

please do not hesitate to contact us because we have myriad ways of developing

functions using our conductors.

|

? |

|

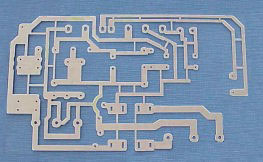

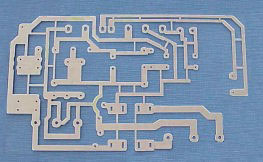

The picture on the left shows that the part, which was

traditionally a pattern of a printed substrate , is pressed with thickness 0.4

items.

(The product in the picture is custom design.) |

|

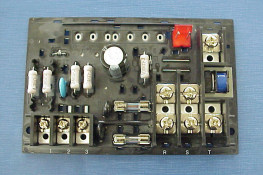

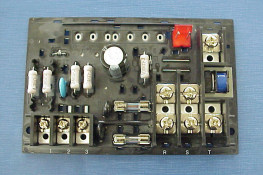

This picture shows how the pattern part of the substrate in above picture was

processed for insert molding, and the terminal stands were simultaneously

molded.

As you see additional processes of attaching the components on

the substrate are not necessary, we are now able to serve you with laborsaving

and cost-down management. |

|

This is the product one step before the completion. |

|

Please use Request Form below for more information |